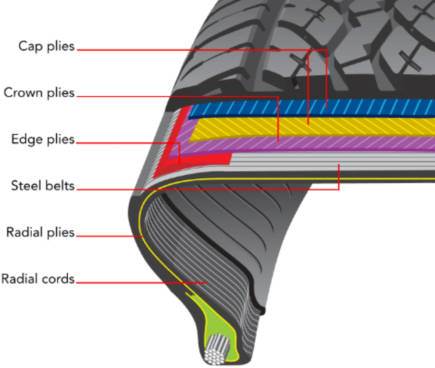

Below are the component parts of a modern radial tire.

TIRE INNER LINER

The inner liner is the first layer on the inside of a tire. It is designed to help prevent air loss.

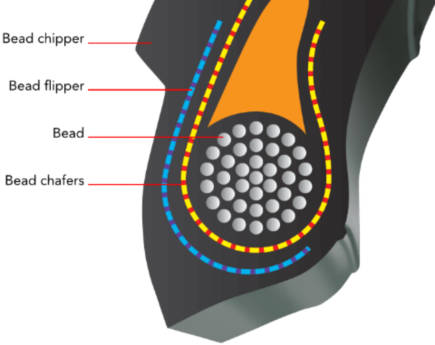

TIRE BEAD AND BEAD CHAFFERS

The beads of a tire form the contact point between the tire and the wheel. They are made with high-tensile-strength steel wires and are surrounded by a hardened rubber compound. They ensure an airtight seal between the wheel and the tire. Bead chaffers rest between the bead and the body ply of the tires, preventing the bead wires from damaging the tire casing and improving the tire's handling by making the sidewall above more responsive.

TIRE SIDEWALL

The sidewall of a tire performs many different and important functions. It protects the inner layers from abrasions and cuts. Manufacturers can vary the handling characteristics and load capacities of a tire by changing the sidewall construction. For example, a stiffer sidewall may lead to more predictable handling but will compromise road quality.

The sidewall is also the location of important tire information such as size, load and speed rating and maximum air pressure.

TIRE CASING

The tire casing is the internal structure that is made up of radial ply, the steel belt package and the cap ply.

TIRE RADIAL PLY

The radial ply is one of the most important layers of the tire casing. It consists of rubber-bonded cords that run across the circumference of the tire at 90 degrees from the direction of tire travel. Radial construction helps absorb bumps from driving surfaces and allows the tread and sidewall to operate independently. This reduces flex in the tread, friction and transverse slip which leads to increased fuel efficiency, more responsive handling and longer tread life.

TIRE BELT PACKAGE

The tire belt package performs multiple functions including protecting the tire casing from road damage and creating the flat area for the tire tread. The belt package is constructed with woven strands of high-strength steel fibers, which are bonded to the rubber. The belt package enhances tire rigidity while remaining flexible enough to absorb bumps in the road.

TIRE CAP PLY

Cap plies are used in performance tires and higher quality all-season tires. The cap ply fights centrifugal forces and contains the belt package by maintaining the tire shape at high speeds, leading to better braking and handling.

TIRE TREAD AREA

A tire's tread area is made up of different features that work cooperatively to provide traction, handling and ride feel. These features vary depending on the intended use of the tire.

Circumferential grooves are channels that run the full length of the tire and help reduce hydroplaning by evacuating water away from the tread surface. They also help reduce tire noise by allowing air to pass under the tire.

Lateral grooves are channels that run 90 degrees from the direction of travel, enhancing traction by removing water, snow and mud from the tread design.

Sipes are thin slits for enhanced grip in wet and icy conditions.

Solid or semi-solid ribs are tread block features that run unbroken around the circumference of the tire. It enhances handling performance and dry weather traction. Large individual tread blocks increase dry weather traction by placing more rubber in contact with the driving surface.

The shoulder features of a tire may vary quite a bit. Some tires utilize a solid shoulder to reduce road noise and improve cornering response. Others use grooves to channel away water, snow and mud. Some may feature aggressive protrusions that add grip in off-road driving situations.

One of the key features of a tire's traction is the rubber compound.

TIRE TREAD COMPOUND

One of the most important components of a tire's tread is the tread compound. The compound varies from tire to tire based on the tire's intended use.

For example, winter tires are made with a compound that is designed to remain flexible when the temperature drops below 45 degrees. This helps ensure traction even in harsh winter conditions.

On the other hand, summer performance tires are designed to perform at very high temperatures and very high speeds. They lose functionality in colder temperatures.

All-season tires attempt to meet a broad set of consumer needs. The compound for an all-season tire is generally designed to supply dependable traction in dry, wet and light snow conditions. It is also designed to deliver more wear resistance. Tread compound is one of the most difficult and complex tire features to design due to the often conflicting nature of tire performance demands.

Refer to the diagrams below for a better understanding of the elements that make up a tire.

Tire Tread

Tread Area (contact patch): The part of the tire that comes into contact with the road. The tread type is distinguished by the design of its ribs and grooves.

Shoulder: The part of a tire where the sidewall and tread meet. Certain tire designs feature shoulder blocks for better traction

Grooves: The space between two adjacent tread ribs; also called tread grooves.

Sipes: Cuts in tread blocks for water evacuation and biting edges on road surfaces.

Tread blocks: Form the tread pattern for wear resistance, stability, and traction.

Tire rib: Part of a tire tread pattern created by grooves that run circumferentially around the tire.

Belt Package

Cap plies: Maintain tread contour shape at high speeds to reduce heat build-up and impart rigidity to tread for enhanced grip.

Crown plies: Provide centrifugal and lateral rigidity to the tire, while also allowing the tire to flex sufficiently for a comfortable ride.

Edge plies: Reinforces shoulder shape of the tire for enhanced handling and grip.

Steel belts: Reinforces the tread region, providing flexibility and ride comfort.

Radial plies: Tire construction where the cords in the body run at 90 degrees to the centerline of the tread.

Radial cords: Run along the sidewall to allow for spring-like flexibility as a way to supply ride comfort.

Tire Bead

Bead Chipper: Protects the lower sidewall

Bead Flipper: Helps hold the bead in place

Bead: The beads are responsible for clamping the tire firmly against the rim of the wheel

Bead Chafers: Protects the wire bead components

Have questions? Do you need help choosing the right tire? We can help you choose what tire is right for you with Treadwell, our intuitive and easy tire buying guide. Just input your vehicle, commute and road conditions and other important factors to get the perfect tire recommendation!

Once you purchase your tires (or if you need a consultation), you can schedule an appointment online.

Get a shorter wait time in-store when you buy and book online!